Freeze drying (also known as lyophilization) is a water removal process typically used to preserve perishable materials, with the goal of extending their shelf life and/or preparing them for transport. Freeze drying works by freezing the material, then reducing the pressure and adding heat to allow the frozen water in the material to change directly to a vapor (sublimate).

冷冻干燥(也称为冻干)是一种除水工艺,通常用于保存易变质的物质比如药品,疫苗,检测试剂等,目的是延长其保质期和/或为运输做好准备。冷冻干燥的工作原理是冷冻材料,然后降低压力并增加热量,使材料中的冷冻水直接变成蒸汽(升华)。

How does Freeze Drying work?

冷冻干燥是如何工作的?

Freeze drying occurs in three phases:

冷冻干燥分为三个阶段:

Freezing

预冻

Primary Drying (Sublimation)

主要干燥(升华)

Secondary Drying (Adsorption)

二次干燥(解析干燥)

Proper freeze drying can improve the efficiency or failure of freeze drying.

合理的工艺可以让冻干效率大大提高和冻干失败

Freezing Phase

预冻阶段

Freezing is the most critical phase of freeze drying, and there are many methods for it. Freezing can be done in a freezer, a chilled bath (shell freezer) or on a shelf in the freeze dryer. Cooling the material below its triple point ensures that sublimation, rather than melting, will occur. This preserves its physical form.

预冻是冷冻干燥最关键的阶段,有很多方法可以做到这一点。预冻可以在冷冻室、预冻浴或冷冻干燥机的架子上进行。将材料冷却到其三相点以下可确保发生升华,而不是熔化。这保留了产品的结构。

Freeze drying is easiest to accomplish using large ice crystals, which can be produced by slow freezing or annealing. However, with biological materials, when crystals are too large they may break the cell walls, and that leads to less-than-ideal freeze drying results. To prevent this, the freezing is done rapidly. For materials that tend to precipitate, annealing can be used. This process involves fast freezing, then raising the product temperature to allow the crystals to grow.

冷冻干燥最容易通过使用大冰晶来实现,这可以通过缓慢冷冻或退火来产生。然而,对于生物材料,当晶体过大时可能会破坏细胞壁,导致冷冻干燥结果不理想。为了防止这种情况发生,冷冻过程需要迅速完成。

对于容易沉淀的材料,可以使用退火。这个过程涉及快速冷冻,然后提高产品温度以允许晶体生长。

Primary Drying (Sublimation) Phase

主干燥(升华)阶段

Freeze drying’s second phase is primary drying (sublimation), in which the pressure is lowered and heat is added to the material in order for the water to sublimate. The vacuum speeds sublimation. The cold condenser provides a surface for the water vapor to adhere and solidify. The condenser also protects the vacuum pump from the water vapor. About 95% of the water in the material is removed in this phase. Primary drying can be a slow process. Too much heat can alter the structure of the material.

冷冻干燥的第二阶段是主干燥(升华),其中降低压力并向材料中添加热量以使水升华。真空加速升华。冷凝器(冷阱)为水蒸气的粘附和凝固提供了一个表面。冷凝器还可以保护真空泵免受水蒸气的影响。在这个阶段,材料中大约95%的水被去除。主干燥可能是一个缓慢的过程。过多的热量会改变产品的结构.

Secondary Drying (Adsorption) Phase二次干燥(解析)阶段

Freeze drying’s final phase is secondary drying (adsorption), during which the ionically-bound water molecules are removed. By raising the temperature higher than in the primary drying phase, the bonds are broken between the material and the water molecules. Freeze dried materials retain a porous structure. After the freeze drying process is complete, the vacuum can be broken with an inert gas before the material is sealed. Most materials can be dried to 1-5% residual moisture.

冷冻干燥的最后阶段是二次干燥(解析),在此期间,离子结合的水分子被去除。通过将温度提高到高于初级干燥阶段的温度,材料和水分子之间的键被破坏。冻干材料保持多孔结构。冷冻干燥过程完成后,在材料密封之前,可以用惰性气体打破真空。大多数材料可以干燥至1-5%的残留水分。

Problems To Avoid During Freeze Drying

冷冻干燥过程中应避免的问题

Heating the product too high in temperature can cause melt-back or product collapse

将产品加热温度过高会导致熔化或产品塌陷

Condenser overload caused by too much vapor hitting the condenser.

过多的蒸汽撞击冷凝器导致的冷凝器过载.

Too much vapor creation

产生过多的蒸汽

Too small a condenser area

冷凝器面积太小

Insufficient refrigeration

/制冷不足

Vapor choking – the vapor is produced at a rate faster than it can get through the vapor port, the port between the product chamber and the condenser, creating an increase in chamber pressure.

蒸汽窒息 – 蒸汽的产生速度快于通过蒸汽口(产品腔室和冷凝器之间的端口)的速度,从而增加腔室压力。

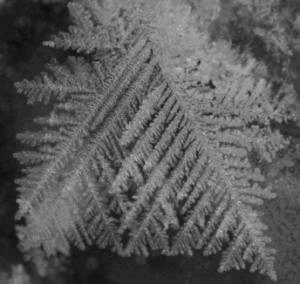

Crystalline结晶

The material forms crystals when frozen.该材料在冷冻时形成晶体。

Has a eutectic point or multiple eutectic points具有一个或多个共晶点

Fast freezing creates small crystals which are hard to dry

快速冷冻会产生难以干燥的小晶体

Annealing can help form bigger crystals

退火可以帮助形成更大的晶体

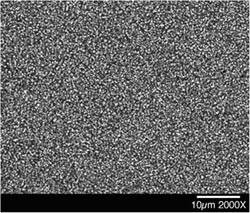

Amorphous 无晶体形态

Multi-component mixtures which do not crystallize and do not have a eutectic point. They turn into a ‘glass.’

不结晶且没有共晶点的多组分混合物。它们变成了一个"玻璃态"。

Does not have a eutectic point没有共晶点

For amorphous materials, freeze drying needs to be performed below the glass transition temperature

对于非晶态材料,需要在低于玻璃化转变温度的情况下进行冷冻干燥。

collapse塌陷

The point at which the product softens to the extent that it can no longer support its own structure. This can be a problem for many reasons:

产品软化到无法再支撑其自身结构的程度。这可能是一个问题,原因有很多:

Loss of physical structure物理结构丧失

Incomplete drying干燥不完全

Decreased solubility溶解度降低

Lots of ablation (splat)大量消融(飞溅)

Critical Temperature临界温度

During freeze drying, the maximum temperature of the product before its quality degrades by melt-back or collapse.

在冷冻干燥过程中,产品质量因熔化或塌陷而下降之前的最高温度。