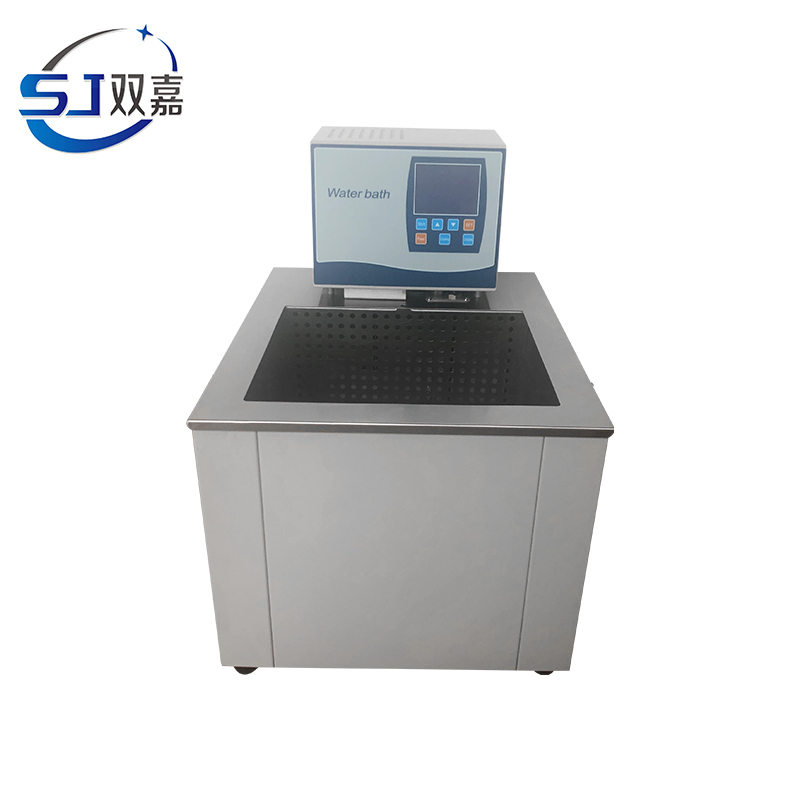

Super digital controlled thermostatic bath, which is the common equipment used in laboratory, is widely used by research departments of such fields as petroleum, national defense, chemical industry, physics, bioengineering, chemistry, medical care, life science, electronic instrument, quality control & metrology, high school, scientific research institution, as well as factory laboratory and metrology & quality control department

I. General introduction

Super digital controlled thermostatic bath, which is the common equipment used in laboratory, is widely used by research departments of such fields as petroleum, national defense, chemical industry, physics, bioengineering, chemistry, medical care, life science, electronic instrument, quality control & metrology, high school, scientific research institution, as well as factory laboratory and metrology & quality control department.

II. Characteristics

The product, which adopts intelligent microcomputer control and is convenient to operate, has good temperature stability and such functions as over temperature alarm and PID automatic control.

Red-green double windows are adopted. The measured values in the up window are red and the set values in the low window is green (LED display).

The deviation in measured temperature value can be revised through the intelligent microcomputer, making the digital display resolution reach 0.1℃.

For special users, PID can be adjustable.

There is internal and external circulation. The external circulation can make the constant temperature-liquid in the bath led outwards, establishing the second constant temperature field.

There is timing function for working hours. Automatic alarm (sending sound continuously) will be performed 2 seconds after the set time is reached, reminding users of the working hours.

There is the function of memory for residual time after power off.

IV. Operating procedure

Add liquid medium into the bath, and the distance between liquid level of the liquid medium and the workbench shall be less than 30mm.

Selection of liquid medium:

Generally, purified water shall be used as the liquid medium when the room temperature is between +8℃-80℃.

Generally, 15% glycerine solution shall be used as the liquid medium when the working temperature is between 80℃-90℃.

Generally, oil shall be used as the liquid medium when the working temperature is above 95℃, and the open cup flash point of the selected oil shall be 15℃ higher than the working temperature. (Note: the working temperature means the temperature that shall be reached by the liquid medium in the bath).

Connection of circulation pump:

Connection of internal circulation pump: Connect the discharge pipe and charge pipe with a hose (one hose is provided).

Connection of external circulation pump: Make the discharge pipe connected to the container inlet outside the bath with hose and make the charge pipe connected to the container outlet outside the bath.

When the super digital controlled thermostatic bath is used, if the working temperature is >90℃, then it is recommended to use metal pipe as the pipe connecting the circulation pump (Note: the pipe at the left front position is discharge pipe, and the pipe at back is charge pipe).

Start the “power supply” switch.

Apparatus operation is as below:

Temperature setting:

Press the “function key for setting” to enter into the temperature setting status. The prompt displayed by the red-number window is “SP”, and the last figure of the green nixie display indicator flashes. Press “add key” or “deduct key” to set the demanded value, then press “shift key” to enter into the status of setting the unit digit of the temperature value, and press “add key” or “deduct key” to set the demanded value. Next, press “shift key” to enter into the status of setting the tens digit of the temperature value, press “add key” or “deduct key” to set the demanded value (by analogy). Press the “function key for setting” to store the set value. At this time, the measured value is the temperature of the liquid medium in the bath, and then the computer will be in automatic control status. The set temperature shall be +8℃ higher than the room temperature.

Other parameters (users must not modify the following parameters at random):

a. SC means measurement correction T: Time cycle P: Time proportion band I: Integral coefficient d: Differential coefficient

b. Press the “function key for setting” for 5s to enter into the status of setting other parameters. At this time, the measured value window displays “SC”. Press “add key” or “deduct key” to set the demanded value. Next, press the “function key for setting”, the measured value window displays “T”, and press “add key” or “deduct key” to set the demanded value. Make all of the parameters modified on the analogy of this, then press the “function key for setting” for 5s to recover to the normal control status and store the set values.

Note: 1. After the working temperature and other parameters are set, press the “function key for setting” to store the set values within 15s, or the original set values will be automatically recovered.

2. Under general conditions, do not modify the parameters without authorization (except modify the measured value revision).

7. After the measured value reaches the working temperature, correspondingly insert the thermograph that meet the experiment requirements. Revise the temperature difference between the measured value and actual bath temperature (the operation method is similar to that under (b) of C of article 6).

V. Time setting

Press the “set key” for above 2s, and the red window displays “ST” and the last figure of values in the green window flashes. Press “add key” or “deduct key” to set the demanded value, and then press the “set key” for operation.

Automatic alarm (sending sound continuously) will be performed 2 seconds after the set time is reached, reminding users of the working hours. At this time, the bumming can be eliminated by pressing any key.

VI. Notes for use:

1. Liquid medium shall be added into the bath before use.

2. 60Hz 220V power supply shall be used. The power shall be larger than or equal to the total power of the instrument, and the power supply shall be provided with good “grounding” device.

3. The instrument shall be placed at a dry place with good ventilation condition, and the distance between the back, two sides of the instrument and barrier shall be above 300mm.

After the instrument is used, all the switches shall be in “off” status; pull out the power plug; pour the water in the bath and remove the water spots.

5. When the temperature is above 60℃, be careful not to touch the surface of the thermostatic bath, so as to prevent scald hands.

Packing List

1. Mainframe 1 5. User Manual 1

2. Power line 1 3. Rubber tube 1

4. Cover board 1 5. Fuse 2